Starch

| Infobox on Starch | |

|---|---|

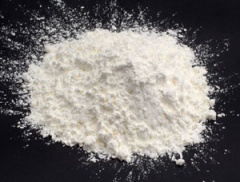

| Example of Starch |  |

| Facts | |

| Origin | - |

| Stowage factor (in m3/t) | 2,12/2,26 (cases) |

| Humidity / moisture | - |

| Ventilation | - |

| Risk factors | See text |

Starch

Description

Pure starch is a white, tasteless and odourless powder that is insoluble in cold water or alcohol.

Starch is a highly organized mixture of two carbohydrate polymers, amylose and amylopectin, which are synthesized by plant enzymes and simultaneously packed into dense water-insoluble granules. Starch granules vary in size (1 to 100 microns [μ m] in diameter) and shape, which are characteristic of their specific plant origin. Starch is the major energy reserve for plants; it is located mainly in the seeds, roots or tubers, stem pith, and fruit. Starch amylose is primarily a linear chain of glucose units. Amylose chains can coil into double helices and become insoluble in cold water. Amylopectin also is composed of chains of glucose units, but the chains are branched. This branched structure renders amylopectin soluble in cold water. The molecular architecture of the amylopectin and amylose within the granules is not entirely understood, but the granules are insoluble in cold water. The functional properties of native starch are determined by the granule structure. Both the appearance of the granules and their functional properties vary with the plant source.

Physical and Functional Properties

In home cooking and in commercial food processing native starches are used for their thickening properties. Starch granules when heated in water gradually absorb water and swell in size, causing the mixture to thicken. With continued heating however, the swollen granules fragment, the mixture becomes less thick, and the amylose and amylopectin become soluble in the hot mixture. This process of granule swelling and fragmenting is called gelatinization. Once gelatinized the granules cannot be recreated and the starch merely behaves as a mixture of amylose and amylopectin. Because of the larger size of the swollen granules compared to the size of amylose and amylopectin, the viscosity of the swollen granule mixture is much higher than the viscosity (the resistance to flow or a liquid or semi-liquid mixture) of the amylose/amylopectin mixture. Starches from different plant sources vary in their gelatinization temperatures, rate of gelatinization, maximum viscosity, clarity of the gelatinized mixture, and ability to form a solid gel on cooling.

The texture of heat-gelatinized starch mixtures is variable. Some gelatinized starch mixtures have a smooth creamy texture, while others are more pastelike. Some starches form gels after cooking and cooling. These starch gels may lack stability and slowly exude water through the gel surface. A similar breakdown of the gelatinized starch occurs in some frozen foods during thawing and refreezing. Although amylose is soluble in the hot gelatinized starch mixture, it tends to become insoluble in the cooled mixture. This phenomenon is called retrogradation and it occurs when the amylose chains bind together in helical and double helical coils. Retrogradation affects the texture of the food product and it also lowers the digestibility of the product. The proper starches must be employed for the different food products to minimize these problems. Certain starches are good film formers and can be used in coatings or as film barriers for protection of the food from oil absorption during frying.

Native and Modified Starches

The predominant commercial starches are those from field corn (maize), potato, cassava (tapioca), wheat, rice, and arrowroot. Field cornstarch (27% amylose and 73% amylopectin) is the major commercial starch worldwide. Genetic variants of field corn include waxy maize, which produces a starch with 98 to 100% amylopectin, and high-amylose starches, which have amylose contents of 55% , 70%, and higher. Waxy starch does not form gels and does not retrograde readily. High-amylose starches retrograde more extensively than normal starches and are less digestible. Their linear structure enables them to form films.

From the 1940s on the demand for convenience foods, dry mixes, and various processed foods has led to the modification of starches for food use and for other commercial products. These modified starches improve the textural properties of food products and may be more suitable for use in modern processing equipment. The Food and Drug Administration regulates use of the various modified food starches by stipulating the types of modification allowed, the degree of modification, and the reagents used in chemical modification. However, the food label is required only to state that "modified starch" is present. Only a small fraction of the sites available for modification of the food starches are actually modified. Although the degree of modification is small, the properties of the starches are significantly improved. This small degree of modification is sufficient to give a more soluble and stable starch after cooking. The clarity of the gelatinized starch as well as the stability of the cooked starch and starch gels are improved. The modification procedures are carried out under mild conditions that do not cause gelatinization of the native starch granules, and therefore the functional properties of the granule are preserved. The emulsifying properties of starch also may be improved by proper modification, improving the stability of salad dressings and certain beverages.

Physically modified starches include a pregelatinized starch that is prepared by heat-gelatinization and then dried to a powder. This instant starch is water-soluble and doesn't require further cooking. Because of its lower viscosity resulting from loss of granule structure, the starch can be used at higher concentrations. Certain confectionaries require high levels of starch to give structure to their products. These gelatinized instant starches serve this role. Cold water swelling starches represent a different type of instant starch. They are made by a proprietary process that retains the granule structure but lowers the granule strength. These cold water swelling starches give higher viscosities than the other instant starches. They are used in instant food mixes and for products such as low-fat salad dressings and mayonnaise.

Plant breeding has led to specialty starches with atypical proportions of amylose and amylopectin. Waxy maize starch with nearly 100% amylopectin is inherently stable to retrogradation. Chemically cross-linked waxy maize starch is a very high-quality modified starch. High-amylose starches have become available more recently and have led to lower caloric starches. Because of the crystallinity of these starches they are partially resistant to digestion by intestinal amylases and behave as dietary fiber when analyzed by the official methods of analysis for dietary fiber. Some of these high-amylose starches contain as high as 60% dietary fiber when analyzed.

The nutritional value of uncooked (ungelatinized) starchy foods (cereal grains, potato, peas, and beans) is relatively poor. The digestive enzymes do not readily convert the native granular starch of uncooked fruits and vegetables into glucose that would be absorbed in the small intestine. Undigested starch passes into the large intestine where, along with dietary fiber, it is broken down to glucose and fermented to short-chain fatty acids. Some of these short-chain acids are absorbed from the large intestine resulting in recovery of some of the caloric value of the native starch.

Starch-Derived Dextrins and Corn Syrups

Modified starches as described above were developed to improve starch functionality in foods as well as their ability to withstand the physical forces of modern food processing systems. In addition to the food applications of starches and modified starches, the native starches are also converted into other products that serve food and other industries. These products do not require the granular character of native starches, which is lost by chemical or enzymic action during processing of the starch.

Dextrinization, a process requiring high temperatures and acid that has been in use since the early 1800s, converts native starch into dextrins that are composed of amylose and amylopectin chains of smaller sizes and altered structure. Consequently, food and nonfood industries have access to a range of dextrins of varying molecular sizes, solubility, and viscosity, but without the granular characteristics described above. Corn syrups are made in the same way as the dextrins, but they are converted to a higher degree such that glucose is a major ingredient. The more recent availability of an enzyme that converts glucose into fructose has led to a new industry in high-fructose corn syrups, which have found a strong market in beverages.

Application

Grade: commercial, powdered, pearl, laundry, technical, reagent, edible, USP.

Use: adhesive (gummed paper and tapes, cartons, bags, etc.), machine-coated paper, textile filler and sizing agent, beater additive in papermaking, gelling agent and thickener in food products (gravies, custards, confectionery), oil-well drilling fluids, filler in baking powders (cornstarch), fabric stiffener in laundering, urea-formaldehyde resin adhesives for particle board and fibreboard, explosives (nitrostarch), dextrin (starch gum), chelating and sequestering agent in foods, indicator in analytical chemistry, anticaking agent in sugar, face powders, adherent and mold-release agent, polymer base.

Shipment / Storage / Risk factors

Starch is usually packed in bags or cases.

Should be stowed apart from odorous, wet or oily goods. Liable to take taint, heat and cake when wet.

See also Flour