Bulk Bags

| Infobox on Bulk Bags | |

|---|---|

| Example of Bulk Bags |  |

| Facts | |

| Origin | |

| Stowage factor (in m3/t) | |

| Humidity / moisture | |

| Ventilation | |

| Risk factors | |

Bulk Bags

Contents

Description / Application

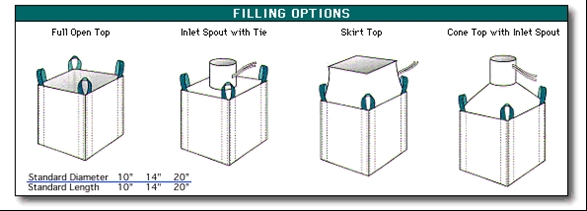

Examples of bulk bags types are as follows and made to be used for dry granulated/powder/seed/bean type commodities and are suitable for use in dry STEEL & VENTED CONTAINERS:

A Flexible Intermediate Bulk Container, FIBC, big bag, bulk bag is a container in large dimensions for storing and transporting dry, flowable products, for example sand, fertilizers, and granules of plastics.

FIBCs are most often made of thick woven polyethylene or polypropylene, either coated or uncoated, and normally measure around 110 cm or 45-48 inches in diameter and varies in height from 100 cm up to 200 cm or 35 to 80 inches. Its capacity is normally around 1000 kg or 2000 lbs, but the larger units can store even more. The average bulk bag made to ship one metric ton can weigh between 5-7 lbs.

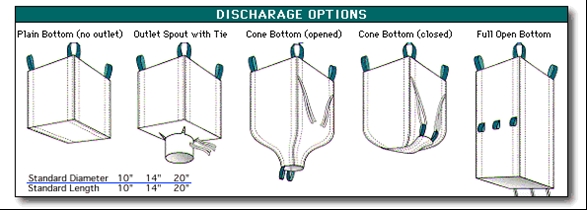

Transporting and loading is done on either pallets or by lifting it from the loops. Bags are made with either one, two or four lifting loops. The single loop bag is suitable for one man operation as there is no need for a second man to put the loops on the loader hook. Emptying is made easy by a special opening in the bottom such as a discharge spout, of which there are several options, or by simply cutting it open.

Classification of FIBCs

Construction

- U-Panel construction

- Circular/Tubular construction

- Baffle construction

- Four side panel construction

- Round construction

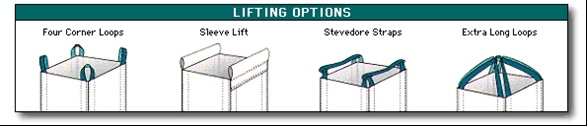

Lifting options

- Cross corner lifting loops

- Corner lifting loops

- Four loops

- Two loops

- Sling loops

Electrostatic properties

- Type - A - no special electrostatic safety features

- Type - B - Type B bags are not capable of generating propagating brush discharges. The wall of this FIBC exhibits a breakdown voltage of 4 kilovolts or less.

- Type - C - Conductive FIBC. Constructed from electrically conductive fabric, designed to control electrostatic charges by grounding. A standard fabric used contains conductive threads or tape.

- Type - D - Anti-static FIBCs, essentially refers to those bags which have anti-static or static dissipative properties without the requirement of grounding.

Industries Served

- Chemicals

- Fertilizers

- Fiberglass

- Food Products

- Grains

- Mining (Used to hold shotcrete)

- Construction (Sand, gravel)

- Pharmaceuticals

- Pigments

- Plastics

- Refractories

- Rubber Additives

- Seed

- Peanuts

- Starch

- Wall coat powder

The popularity and use of bulk bags will continue to grow as handling becomes increasingly easier and cost savings are even more readily identifiable over other types of packaging. Intermediate bulk containers will also continue to thrive due to:

- Ease of handling;

- Space saving when compared to rigid boxes or totes;

- Hygienic considerations at discharge;

- Lower cost of disposal of used packaging;

- Labor cost savings, particularly at discharge;

- Reduction of waste ingredient;

- Conducive for road, rail or container shipment;

- Environmentally friendly - ability to reuse and/or recycle bags

See also: www.FIBCA.com - the Flexible Intermediate Bulk Container Association (FIBCA).