Ores unprocessed

| Infobox on Ores unprocessed | |

|---|---|

| Example of Ores unprocessed |  |

| Facts | |

| Origin | origin =

|

| Stowage factor (in m3/t) | stowage factor =

|

| Humidity / moisture | humidity and moisture =

Actual moisture: various |

Actual moisture: various |

| Ventilation | Surface ventilation |

| Risk factors | Liquefaction, loss of ship's stability |

Ores unprocessed

Contents

Description

A large range of ores are shipped in unprocessed condition. This category includes two particular type of unprocessed ores which have led to high profile casualties involving the loss of life of dozens of seafarers as a result of the cargoes liquefying on board during transit. Apart from a number of tragic losses, there is also record of several “near-misses” and time consuming charter party disputes as a result of shipping these cargoes.

The cargoes in question are:

- Lateritic nickel ore from Indonesia, Phillipines, New Caledonia

- Iron ore fines from India

There have also been reports raising concern on similar problems with sinter feed cargoes from Brazil, chromite ore and mill scale.

Lateritic nickel ore

This ore has a rusty-red colour, which is typical for all laterite soil types which are inherently rich in iron and iron oxides. The appearance is that of a heterogeneous mixture of fine clay-like and larger rock-like particulars. The iron oxide and clay minerals host mineral for nickel but also for instance cobalt. The amount of nickel found in these ores is low, typically not more than 2%.

Origin

Lateritic (nickel) ore develops by long-lasting weathering of the parent rock and particularly occurs in tropical areas with a repetition of wet and dry seasons. The majority of the world’s nickel resources are contained in these laterites and account for a large proportion of the world’s nickel production. The main areas in the world with the largest nickel laterite sources are New Caledonia, Australia, the Phillipines and Indonesia, for the latter mainly the island of Sulawesi. Main shipment locations in the Philippines are Rio Tuba (Palawan), Surigao and Tubay (Mindanao) and Santa Cruz (Luzon).

Mining process / logistics

The ore is simply dug out of the ground by heavy duty earthground equipment. The mining places are remote areas with little or no direct loading facilities for overseas transportation. Inland transportation takes place in open trucks and the loading stockpiles are located on open areas and beaches. The ore is usually transported to ocean going vessels at anchorages nearby the mines, by means of (open) barges. In 2011, some 400 million tons of laterite nickel ore was shipped this way from Indonesia to China, supplying cargo to thousands of bulk carriers on an annual basis.

Application

Nickel is one of the most sought after metals in the industrial world for its use in magnets, coins, rechargeable batteries, and most importantly, stainless steel. In fact, roughly two-thirds of global nickel production goes to make stainless steel, and China produces and consumes the majority. The main reason for this is innovative processing techniques developed in China to process the low grade laterite nickel ores into nickel pig iron which has typical nickel contents between approx. 5 and 13%. These production processes have always been more difficult than the processing of the more commonly nickel sulphide.

China’s innovation in processing low-grade nickel ore has firmed up the country as the world leader in both nickel laterite consumption and stainless steel production. As a consequence China may be seen as the first country which opened up the market on low-grade nickel ores. Whereas traditionally two-thirds of the world’s refined nickel has gone into stainless steel production, the pig iron substitute would allow refined nickel to be redirected to, for instance the application into the production of batteries for electric vehicles.

Iron ore fines

Iron ore fines is a grey / rusty-red coloured fine sized material, shipped in bulk. Incidents with liquefying cargo on board seagoing vessels have been reported with iron ore fines loaded at the Indian ports of Mangalore and Paradip.

Iron ore is a natural material that is mined all around the world. Iron ore fines are created as a result of mining, crushing and processing the larger pieces of ore. Iron ore fines are less desirable (and of lower value) as they need to be sintered before they can be utilised, otherwise it will effectively smother the air flow in the blast furnace. The reason lump is preferred is that when it is fed into a blast furnace for steel-making, its particle size allows oxygen or air to circulate around the raw materials and melt them efficiently. Industry standards typically place iron ore lumps into the size range of 6 to 31 mm, and iron ore fines at particles of less than 6 mm. The iron content of the fines is typically above 60%.

Application

Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. China is the largest consumer of iron ore, which translates to be the world's largest steel producing country. It is also the largest importer.

Sinter feed

Sinter feed is an iron concentrate containing fine particles and moisture. It has a dark grey to red / rusty colour. Stability problems have been reported on board ocean going vessels which had loaded sinter feed cargoes at Ponta Madeira, Brazil. Stability problems were reportedly caused by liquefaction / free water separation resting on top of the cargo.

Application

Sinter feed is used for manufacturing of steel. Due to its fine grained size, it requires sintering before it can be added into the blast furnace.

Risks

Liquefaction

Albeit that the above mentioned cargoes are not listed as such in the relevant IMSBC Publication (situation 2012), they must be considered as cargoes which include a significant risk of liquefaction (Group A). Liquefaction is the transition process of a cargo from a solid state to a viscous fluid state by which all or part of the cargo can flatten out to form a fluid surface. In this form the liquefied cargo may (unexpectedly start to) flow from one side of the ship’s cargo hold to the other. In naval architecture this is called a “free surface effect”, which causes a dramatic reduce of the ship’s metacentric height (GM) or stability. The effect primarily increases with the width of the hold, the free surface moment thereby defined as the resultant from the formula:

FSM = 1/12 x length x width3

As a consequence, the effect of the hold width over which the liquid can flow has a reduction effect on the ship’s stability, by the third power. The process of liquefaction, results from compacting of the cargo during transit as a result of the vibrations and motions which inherently occur during a seagoing voyage. Liquefaction will not occur if the moisture content of the ore to be shipped is sufficiently low. The exact moisture amount for each product or origin of product cannot be given as this largely depends on a range of other factors, amongst which composition and particle size. The following terms are applicable when considering cargoes liable to liquefaction:

Flow Moisture Point (FMP)

This is the lowest moisture content at which liquefaction can occur. Only a laboratory test can determine the Flow Moisture Point.

Transportable Moisture Limit (TML)

The numerical TML value is calculated at 0,9 times the FMP value. It is the result of a simple formula and not determined in the laboratory (except than for the FMP value as indicated above). The 10% margin between the TML and the FMP is to provide for a safety margin (measurement uncertainties etc.)

Moisture limit (ML)

This is the actual moisture content of a (representative) sample from the stockpile or part of the cargo to be loaded.

In order to avoid liquefaction, the moisture limit needs to be less than the TML.

Under the applicable IMO provisions, shippers have to deliver appropriate cargo information as to whether the cargo may liquefy. This information should include a declaration of the moisture content and the TML. (this principle would apply to any bulk cargo that contains moisture and fine particulars and that has been tested in a laboratory to possess flow properties).

Particular problems occur with iron ore fines and lateritic nickel ore in that these cargoes are usually non-homogeneous in composition and origin and lack uniform moisture contents. Change or difference in moisture content within the parcel or throughout the logistic chain can be the result of the following:

- Difference in moisture content of the product from different mining pits (or even within the same mine)

- Rainfall during inland transportation

- Rainfall and storage conditions during storage (stockpile)

- Rainfall during barge transportation incl. possible free water in the barge.

- Sea wateringress during storage / transportation on board.

As regards the seasonal weather conditions in the tropics (monsoon, wet / dry season), the risk of the cargo becoming increasingly wet is logically higher during the monsoon and wet seasons. It should however be mentioned that (probably due to climate change as well) heavy rain also may occur during the dry season and off-monsoon periods.

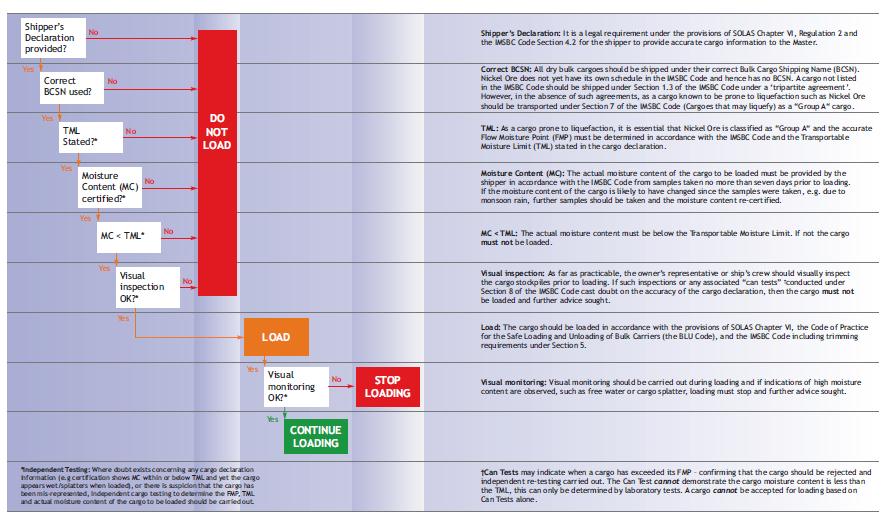

In order to ensure that the cargo as shipped or intended to be shipped on board meets the requirements in the IMSBC Code in order to avoid liquefaction, reference is made to the relevant sections in this Code on liquefying cargoes (group A). The International Association of Dry Cargo Shipowners (Intercargo) published the following schematic overview as an aid to assist masters in deciding whether to load cargo or not.

Reference is made to the relevant IMO regulations of hazardous cargo.

See also:

http://www.standard-club.com/media/23989/StandardCargoLiquefactionFeb2011.pdf

http://www.slideshare.net/no2mininginpalawan/nickel-ore-and-dangers-liquefaction

http://www.american-club.com/files/files/Liquefaction_Solid_Bulk_Cargoes_Nickel_Ore.pdf